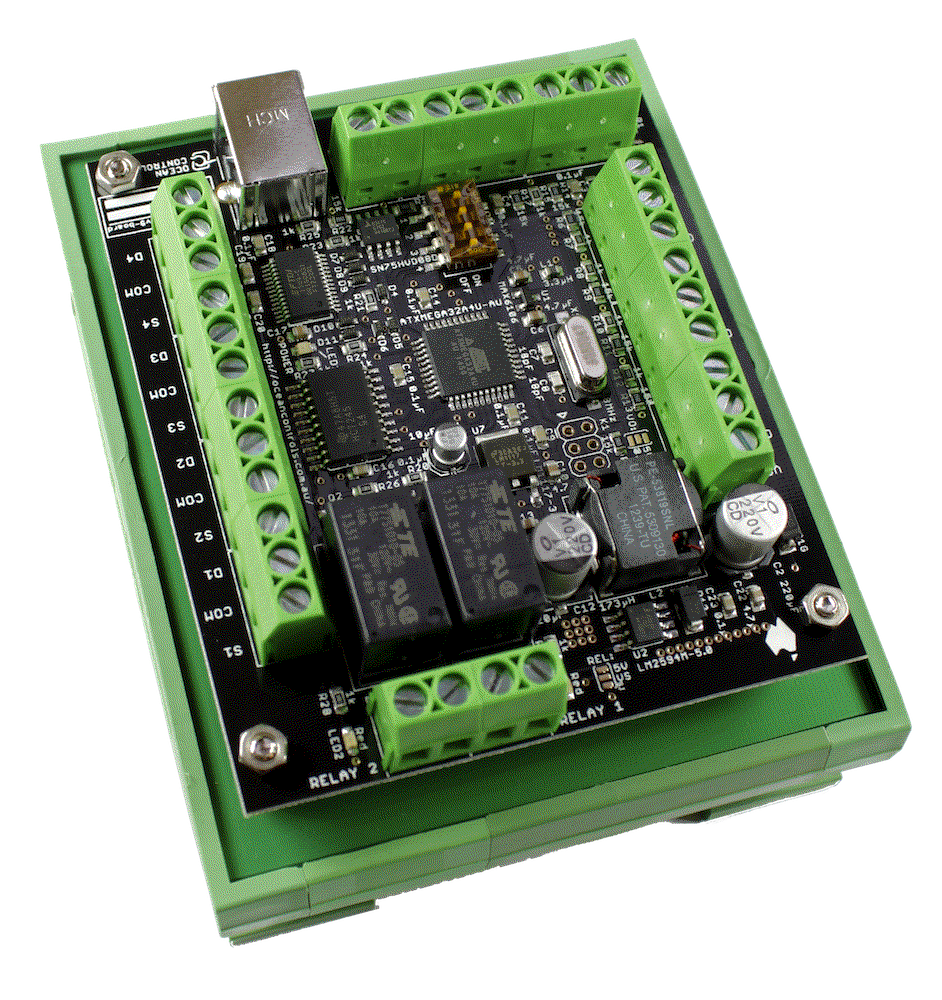

Description: The KTD-290 is a our KTA-290 USB or RS-485 controller card with a DIN rail mounting adapter.

The KTA-290 is a USB or RS-485 controller card that generates the pulses to feed to up to four axes of stepper or servo motor drivers. Simple commands allow the independent motion of the motors. The controller is an upgraded version of our popular KTA-190.

The step and direction outputs of the card can connect directly to almost any stepper or servo motor driver, including the full range of our Leadshine motor drives.

Once connected to a computer, the card appears as a virtual serial (COM) port. The card also acts as a USB to RS-485 serial converter, allowing you to multidrop up to 4 interface cards off the RS-485 serial line. This allows control of up to 16 axes of motors.

The KTA-290 is a major improvement over our KTA-190, featuring more accurate frequency generation, smoother ramping and USB communication. It uses many of the same simple ASCII commands.

Motors connected to the 290 are controlled using simple ASCII commands. Any terminal program (Hyperterm, TeraTerm, RealTerm etc.) or programming language capable of sending strings out a serial port can be used to generate the strings for the controller. We provide a free Windows example program with Visual Basic source code that allows a sequence of commands to be sent out the serial port.

New Version: Now with analog inputs and can be powered from 8 to 35 VDC.

Examples of the commands:

@01 AMOV 1000 2000 4000 do an absolute move of stepper 1,2 and 3 to positions 1000, 2000 and 4000@01 AMOV 2000 do an absolute move of stepper 1 to position 2000@02 RMOV -400 do a relative move of stepper 2 400 steps backwards @03 POSN 10000 indicate stepper 3 is at position 1000 @04 STOP stop all motors connected to the card@01 STAT card sends the status of motors 1 to 4 whether they are moving or not and status of limit switches.

Please note these are not G-Code commands and it will not accept G-Code

Positions are stored internally as signed, 32 bit integers allowing for a range of more than ±2 billion steps

The user can also set the acceleration and deceleration rates when starting and ending a sequence of steps. Limit switch inputs are available for each of the motors to prevent motors moving out of range.

The card also features 2 relays which can be switched on or off or on.

Features:

- Power Supply: 8 to 35VDC

- Power Consumption: ~1.5W + External 5V drain

- Operating Temperature: 0 to 70°C

- 2 x Analog Inputs: accept 0 to 32VDC

- 2 x Limit Switch Inputs: for each motor

- 2 x Auxiliary Input-Outputs: accept 0 to 2.048VDC

- 2 x Relay Outputs: for controlling, SPST relays, switch to 5A and 30VDC

- 4 x Step and Direction Outputs: 5 VDC signal levels

- Controls 4 axes of stepper or servo motors simultaneously

- Up to 40 kHz max stepping rate

- Protocol: ASCII protocol

- USB Virtual serial port or RS-485 input

- Easily connect multiple units by RS-485 for up to 16 axes

- Baud rate selectable

- Parameters can be stored in non-volatile EEPROM

- XOR checksum option

- DIN rail mount

- Dimensions: 92L × 78W × 25H (mm)

A typical complete stepping system should include a stepping motor, stepping driver (e.g. M542), power supply and a controller (pulse generator), e.g. KTD-290.

Documentation and Downloads